Thermal Imaging

MOLEC Thermal Imaging

To help cope with the fast pace of the world in which we live today, where no company can afford to have shut downs due to faults occurring within their plant MOLEC Electrical can offer a number of preventative maintenance solutions.

One of the preventative maintenance solutions we offer is “Electrical Distribution Board Maintenance” and thermography services in Melbourne. Electrical distribution boards are the focal point of every production plant and fast paced business. It is our belief and is also regularly required by insurance underwriters that both from a preventative maintenance and OH&S point of view that electrical distribution board maintenance should be carried out annually. This not only helps to keep a plant up and running but also helps to prevent injury to employees in the way of electrical faults.

The general inspection allows MOLEC to identify any physical damage to a DB and also helps to identify missing covers or parts from a DB. Our Thermography services will assist in the identification any damaged cables and any break down in a Distribution Boards IP rating which can lead to major issues if not identified as early as possible.

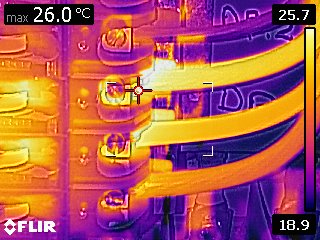

Thermal Imaging in Laverton North allows the identification of hot spots within electrical distribution boards and therefore helps to prevent electrical fires from occurring within the DB. The identification of the hot spots also helps to prevent break downs as often it can be a problem with the motor or equipment connected to the circuit that can be causing the hot spot. Once hot spots are discovered MOLEC will find the cause and advise on the best solution. Above are some examples of thermal images taken from of our electrical distribution board inspections

All terminations within a Distribution Board should be check annually as the various stresses a Distribution Board is put under over a year can cause terminations to become loose. Examples of these electrical thermal imaging are weather conditions, operating in cool conditions in winter and then having to operate at 40+oC in summer. The heating and cooling of circuits on a daily bases also adds to the possibilities as mental expands and contracts with the heat this causes loose terminations.

All DB’s must be labelled in accordance with AS/NZS 3000 and circuits correctly identified.

A complete clean and vacuum of Distribution Boards' is recommended as the build up of dust and dirt within Distribution Boards' can often be the cause of the breakdown of electrical components within a Distribution Board.